4-hour load bank test requirements: Navigating the intricate world of electrical testing, this guide breaks down the crucial steps for a smooth, safe, and effective 4-hour load bank test. From initial setup to final report, we’ll cover everything you need to know, keeping safety front and centre.

Understanding the intricacies of voltage, current, and power specifications is key. This comprehensive Artikel delves into the necessary equipment, procedures, and data analysis to ensure your 4-hour load bank test meets industry standards. Safety protocols are paramount, so expect thorough guidance on precautions and potential issues. This isn’t just a test; it’s a critical evaluation, and a solid grasp of the requirements is essential for accurate results.

Introduction to Load Bank Testing

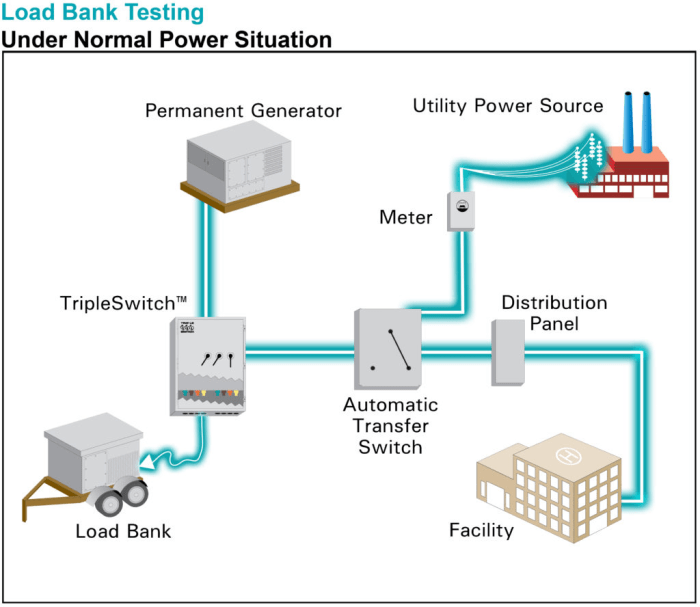

Load bank testing is a critical component of power system and electrical equipment evaluation. It involves subjecting electrical equipment, such as generators, transformers, and power distribution systems, to controlled and precisely defined loads to assess their performance under stressed conditions. This process is crucial for determining the equipment’s operational limits, stability, and overall reliability.A 4-hour load bank test, in particular, is designed to simulate sustained, realistic operational loads over an extended period.

This allows engineers to observe the equipment’s behavior under prolonged stress, crucial for identifying potential weaknesses or instability issues that might not manifest during shorter tests. The primary objectives of a 4-hour load bank test are to evaluate the equipment’s thermal stability, voltage regulation, and overall performance under continuous high-load conditions. This extended duration provides valuable insights into the equipment’s ability to handle sustained operation at rated capacity or beyond.

Significance of Load Bank Tests

Load bank testing plays a vital role in various industries, including power generation, transmission, and distribution. The data collected during these tests is instrumental in making informed decisions about equipment selection, maintenance schedules, and operational strategies. Accurate assessments minimize the risk of equipment failure during peak demand periods, leading to improved reliability and safety. Moreover, these tests are often a mandatory component of equipment certification and acceptance procedures, ensuring adherence to safety standards and regulatory requirements.

This ultimately contributes to the reliability of the entire power system.

Types of Load Bank Tests

The duration and specific objectives of load bank tests vary based on the equipment being tested and the desired level of analysis. Different types of tests cater to different needs.

| Test Type | Duration | Objectives | Applications |

|---|---|---|---|

| Short-Term Load Test | Minutes to Hours | Evaluating the equipment’s immediate response to varying loads, assessing transient stability, and identifying any initial anomalies. | Assessing the initial response of the system, confirming the equipment can handle short bursts of high load. |

| Long-Term Load Test | Days or Weeks | Evaluating the equipment’s performance under sustained load conditions, analyzing long-term thermal stability, and identifying potential degradation over time. | Assessing the equipment’s sustained performance and identifying long-term issues such as insulation degradation or thermal runaway. |

| 4-Hour Load Bank Test | 4 Hours | Simulating sustained, realistic operational loads, observing the equipment’s behavior under prolonged stress, evaluating thermal stability, voltage regulation, and overall performance under continuous high-load conditions. | Commonly used to assess the performance of power generation equipment, ensuring it can meet sustained operational demands. |

These diverse types of tests offer a comprehensive understanding of the equipment’s capabilities under different operating scenarios, ultimately contributing to improved system reliability and safety.

Test Requirements and Standards

A 4-hour load bank test provides a rigorous evaluation of a system’s performance under sustained high-load conditions. This test critically assesses the system’s ability to maintain stability, efficiency, and safety parameters throughout an extended period. Thorough adherence to predefined test requirements and industry standards is paramount for accurate results and safe operation.

Voltage, Current, and Power Specifications

The voltage, current, and power specifications for the load bank test must be precisely defined to simulate realistic operating conditions and accurately assess the system’s response. These parameters should be tailored to the specific system under evaluation, considering its rated capacity and anticipated operational demands. Precise control and monitoring of these parameters throughout the 4-hour duration are essential.

For example, a 4000V, 100A load bank would be used for a system rated at 4000V and 100A.

Industry Standards and Regulations

Adherence to relevant industry standards and regulations is crucial to ensure the safety and validity of the load bank test. These standards typically cover electrical safety procedures, equipment grounding, and proper test setup. Examples of applicable standards include IEEE standards for power systems and relevant national electrical codes. These standards mandate safety precautions and procedures to prevent accidents and ensure reliable test results.

Safety Precautions and Procedures

Comprehensive safety precautions and procedures are essential to mitigate potential hazards during the load bank test. Proper equipment grounding, insulation, and isolation techniques are critical to prevent electrical shocks and fires. Personnel conducting the test must be properly trained and equipped with appropriate safety gear, such as insulated gloves, safety glasses, and hard hats.

Safety Measures Summary

| Safety Measure | Description | Importance |

|---|---|---|

| Grounding | Ensuring proper grounding of all equipment and test setup to prevent electrical shocks. | Critical for preventing electrical hazards and ensuring safe operation. |

| Insulation | Using appropriate insulation materials to prevent electrical contact and ensure safety. | Protects personnel from electrical shocks and equipment from damage. |

| Isolation | Separating energized components and equipment from personnel and other equipment. | Minimizes risk of accidental contact and prevents short circuits. |

| Personal Protective Equipment (PPE) | Providing personnel with appropriate safety gear such as insulated gloves, safety glasses, and hard hats. | Protects personnel from electrical hazards and potential injuries. |

| Monitoring | Continuous monitoring of voltage, current, and temperature throughout the test. | Allows for immediate detection of anomalies and enables corrective actions. |

| Emergency Procedures | Having established emergency procedures and personnel trained to handle any unexpected events. | Ensures swift and safe response to any critical situation. |

Equipment and Setup Considerations

Appropriate equipment and a meticulously planned setup are crucial for a successful and reliable 4-hour load bank test. Rigorous adherence to established standards and safety protocols ensures accurate data collection and minimizes potential risks. The chosen equipment must be capable of handling the anticipated load demands throughout the entire test duration.Accurate measurements and consistent monitoring are essential to validate the performance and stability of the system under investigation.

4-hour load bank tests are crucial for verifying the resilience of electrical systems, particularly in high-density residential areas. These tests simulate peak demand, ensuring sufficient capacity to power buildings like low income apartments in Elk River, MN low income apartments in elk river mn , and prevent outages during periods of high usage. The reliability of these tests directly impacts the safety and functionality of the electrical infrastructure.

This involves careful selection and configuration of instrumentation, ensuring it aligns with the test objectives and the specifications of the subject equipment. The setup must be robust and easily repeatable to facilitate future testing and comparisons.

Load Bank Selection and Specifications

The selection of a suitable load bank is paramount. The load bank must be capable of delivering the specified load profile for the duration of the test. Critical factors include the maximum power output, voltage regulation, and the ability to adjust the load current and power. Oversizing the load bank is unnecessary and adds to the cost, while undersizing it could compromise the test results.

Instrumentation Requirements

Precise measurement of key parameters is vital. This includes accurate voltage and current meters, capable of handling the expected high current demands of the test. High-quality, isolated and calibrated instruments are necessary to prevent errors. Moreover, data acquisition systems are essential for capturing and recording the test data, ensuring a complete and accurate dataset for analysis. A dedicated monitoring system that displays critical parameters in real-time is crucial for continuous observation of the system’s performance.

Monitoring System Details

The monitoring system plays a critical role in real-time observation of the system under test. This includes a graphical display of key parameters such as voltage, current, and power. Real-time monitoring allows immediate identification of any anomalies or deviations from the expected performance. Moreover, the system should incorporate alarm thresholds for critical conditions to prevent potential damage to the equipment under test.

Log files should be generated for future analysis and reporting. These records are essential for reproducibility and comparison across multiple tests.

Setup Procedure and Environmental Considerations, 4-hour load bank test requirements

A well-defined setup procedure ensures consistent and repeatable test conditions. Connections must be made meticulously to prevent electrical hazards and ensure accurate data collection. The test environment must be controlled to minimize external factors that could affect the test results. Temperature fluctuations and ambient noise levels should be monitored and controlled. A dedicated area with appropriate safety measures should be designated for the test.

Equipment List and Specifications

| Equipment | Specifications | Justification |

|---|---|---|

| Load Bank | 400 kW, 480V, 3-phase, adjustable load profile | Sufficient capacity for the test duration |

| Voltage Meter | 600V AC, 0.1% accuracy | High accuracy for accurate voltage measurements |

| Current Meter | 1000A AC, 0.2% accuracy | High current capacity and accuracy for load current measurements |

| Power Meter | 400 kW, 0.5% accuracy | Accurate measurement of power consumption |

| Data Acquisition System | High-speed sampling, data logging capabilities | Essential for recording and analyzing data during the test |

| Monitoring System | Real-time display of voltage, current, and power, alarm thresholds | Real-time monitoring and alerting for anomalies |

Test Procedures and Methodology

A 4-hour load bank test provides a comprehensive evaluation of a system’s performance under sustained load conditions. This rigorous procedure is crucial for identifying potential weaknesses, validating design specifications, and ensuring reliable operation under anticipated operational demands. Accurate and methodical execution of the test protocol is paramount to obtain meaningful results.

Step-by-Step Procedure for a 4-Hour Load Bank Test

The test sequence involves a controlled and systematic increase in load, meticulously monitored for critical parameters. This structured approach allows for the identification of any anomalies or deviations from expected performance. The procedure includes the following steps:

- System Initialization: The system under test (SUT) is prepared for testing by connecting to the load bank and ensuring all monitoring equipment is calibrated and operational. Initial readings are recorded for baseline data.

- Gradual Load Increment: A predetermined load increment strategy is implemented to gradually increase the load on the SUT. This methodology is essential to avoid sudden stress on the system, allowing it to adapt and demonstrate stability over time. Precise control over the rate of load increment is critical to ensuring a representative and repeatable test.

- Continuous Monitoring: Key parameters, such as voltage, current, temperature, and system response time, are monitored continuously throughout the 4-hour duration. Real-time data acquisition and analysis are essential for identifying any deviations from expected performance.

- Data Recording and Analysis: Data acquisition systems continuously record all monitored parameters. Simultaneously, observations are meticulously documented, noting any anomalies, alarms, or unusual behavior. This comprehensive data collection allows for post-test analysis and assessment.

- System Stabilization: After the load has reached the target level, the system is allowed to stabilize under the sustained load. The duration of this stabilization period is dictated by the system’s characteristics and should be recorded.

- Load Bank Reduction: Following the stabilization period, the load bank is gradually reduced to its initial value. This ensures that the system returns to its initial conditions and that the test is conducted under a controlled environment.

- Final Readings: Final readings are taken and recorded for comparison with initial data.

Methods for Gradually Increasing Load

Various strategies exist for incrementally increasing the load during the test. These methods should be selected based on the system’s expected response and the specific requirements of the test.

- Linear Ramp: A consistent increase in load over the 4-hour period. This method is suitable for systems with a predictable response to increasing stress. A linear ramp allows for an easy assessment of the system’s response under progressively increasing load. Example: Increase the load by 10% every 30 minutes.

- Stepwise Increment: The load is increased in discrete steps, allowing for assessment at specific load levels. This method is particularly useful for systems that exhibit a threshold-based response to load changes. Example: Increase the load by 20% every hour.

- Adaptive Increment: The load increment rate is adjusted dynamically based on the system’s performance. This method allows for a more nuanced approach, adjusting to the system’s reaction to changing load conditions. Example: Increase the load by 5% if the system response remains within tolerance, or by 1% if there is a deviation from the baseline. This method often requires sophisticated control systems and extensive pre-test analysis.

Importance of Monitoring Key Parameters

Precise monitoring of key parameters during the test is crucial for accurately evaluating the system’s performance under stress. Any deviation from expected behavior can signal potential issues that need immediate attention.

- Voltage Stability: Maintaining a stable voltage output is crucial for the integrity of the system and for reliable operation.

- Current Draw: Monitoring current draw is critical to assess the system’s capacity to handle the applied load.

- Temperature: Monitoring temperature is essential to prevent overheating and potential damage to components.

- System Response Time: Monitoring system response time helps assess the system’s ability to adapt to changing load conditions.

Data Recording and Observation Process

Comprehensive data recording and observation are vital for extracting meaningful insights from the load bank test. This process involves both automated data acquisition and manual observation.

- Automated Data Acquisition: Real-time data acquisition systems should be employed to record all critical parameters at predefined intervals. This approach ensures accuracy and consistency.

- Manual Observation: Detailed observations of system behavior, such as any unusual noises, vibrations, or visual indicators, should be recorded alongside the automated data. These observations can often reveal hidden issues that automated systems might miss.

- Documentation: All recorded data and observations should be meticulously documented in a structured format. This allows for easy retrieval and analysis of the test results.

Critical Parameters to Monitor and Their Tolerances

The following table summarizes the critical parameters to monitor and their respective tolerances during the 4-hour load bank test.

| Parameter | Units | Tolerance |

|---|---|---|

| Voltage | Volts | ±1% of nominal |

| Current | Amps | ±2% of nominal |

| Temperature | °C | ±5°C of baseline |

| System Response Time | Seconds | Within ±10% of initial |

Data Analysis and Reporting

Thorough analysis of the collected data is crucial for interpreting the performance of the system under test during the load bank test. Accurate and comprehensive reporting ensures effective communication of findings and facilitates informed decision-making regarding system improvements or adjustments. The process involves identifying trends, patterns, and potential anomalies in the data, enabling proactive identification of weak points and areas requiring attention.

Data Analysis Techniques

Data analysis involves a multifaceted approach, encompassing statistical methods, graphical representations, and trend identification. Statistical analysis techniques, such as regression analysis, can be employed to establish correlations between load parameters and system response. Graphical representations, including line graphs, bar charts, and scatter plots, are instrumental in visualizing trends and patterns in the data. Trend analysis helps to identify sustained performance improvements or degradations over time.

Pattern recognition techniques, often employed in machine learning, can be utilized to detect anomalies or deviations from expected behavior in the collected data.

Identifying Potential Issues or Anomalies

Careful examination of the data is necessary to pinpoint potential issues. Sudden drops in performance metrics, such as voltage fluctuations or significant increases in current draw, could indicate faulty components or operational problems. Deviations from expected performance curves or trends can signal potential instability or vulnerabilities in the system’s design. Outliers, which represent data points significantly differing from the general trend, should be investigated further to determine if they stem from measurement errors, external factors, or genuine system anomalies.

Monitoring critical system parameters like temperature and frequency, alongside load characteristics, helps to understand the relationship between them and potential issues.

Result Presentation Format

The test results should be presented in a clear and concise format, facilitating easy interpretation. Graphs, charts, and tables are essential for effective data visualization. Line graphs are useful for illustrating changes in parameters over time, such as voltage, current, and power consumption. Bar charts can effectively compare different load conditions or system responses. Scatter plots can reveal correlations between different variables.

Tables provide a structured way to present numerical data, such as specific readings at different time intervals or under various load levels. The report should include detailed descriptions of each graph and table, explaining the trends, patterns, and anomalies observed. Properly labeled axes and legends are crucial for clarity and accuracy.

Test Report Data Points

| Category | Data Point | Description |

|---|---|---|

| System Parameters | Voltage (V) | Measured voltage across the system at various load levels. |

| Current (A) | Measured current drawn by the system at various load levels. | |

| Power (W) | Calculated power consumption of the system at various load levels. | |

| Frequency (Hz) | Measured frequency of the system’s operation. | |

| Temperature (°C) | Measured temperature of critical components. | |

| Load Parameters | Load Level (e.g., kW) | Specific load level applied during the test. |

| Duration (hrs) | Duration of the load application. | |

| Observations | Anomalies | Description of any observed deviations from expected behavior. |

| Measurements | Recorded data points from all measurements. |

This table provides a comprehensive list of data points crucial for documenting the load bank test results. Inclusion of these parameters allows for a detailed analysis and facilitates accurate interpretation of system performance. The table ensures that all essential data is included for comprehensive reporting.

Troubleshooting and Mitigation

During a 4-hour load bank test, various issues can arise, requiring prompt identification and mitigation to ensure accurate results and prevent damage to the tested equipment. Effective troubleshooting involves a systematic approach, focusing on identifying the root cause of any observed anomalies and implementing appropriate corrective actions. Proper risk assessment is crucial to minimize potential hazards and maintain a safe testing environment.

Common Issues During Load Bank Testing

Several factors can contribute to unexpected outcomes during a 4-hour load bank test. These include variations in power supply characteristics, fluctuations in ambient temperature, and potential equipment malfunctions. Careful monitoring of critical parameters, such as voltage, current, and temperature, is essential to detect and address these issues proactively.

Solutions and Troubleshooting Steps

A structured troubleshooting process is essential for resolving issues that may arise. This involves systematic checks of equipment functionality, power supply stability, and environmental conditions. Careful logging of test data, including any deviations from expected parameters, aids in pinpointing the source of the problem. For instance, if voltage drops significantly during the test, it’s crucial to investigate the power supply’s capacity and connectivity.

Identifying and Mitigating Potential Risks

Risk assessment is paramount to prevent unforeseen issues and potential damage during the test. Potential risks include equipment failure, fire hazards, and electrical shocks. Rigorous safety protocols, including proper grounding and insulation, must be implemented to minimize these risks. For example, if a load bank is operating outside its specified capacity, the risk of overheating and potential fire increases significantly.

A pre-test safety inspection should identify and mitigate such potential hazards.

Table of Common Issues and Solutions

| Issue | Possible Cause | Troubleshooting Steps | Mitigation |

|---|---|---|---|

| Voltage Fluctuations | Inadequate power supply capacity, faulty wiring, or ground issues. | Verify power supply capacity, check wiring connections for tightness and proper grounding, and assess for any ground faults. | Ensure sufficient power supply capacity, use high-quality wiring, and maintain proper grounding. |

| Unexpected Current Draw | Equipment malfunction, incorrect load bank setting, or short circuits. | Verify equipment operation, confirm the load bank settings, and check for any visible signs of damage or short circuits. | Ensure correct equipment settings and regularly inspect for potential damage. Perform periodic load bank maintenance. |

| Excessive Temperature Rise | Overloading of equipment, insufficient cooling, or malfunctioning cooling systems. | Monitor equipment temperatures, check for airflow obstructions, and ensure cooling systems are functioning correctly. | Implement adequate cooling measures, and adjust load bank settings to avoid overloading. |

| Equipment Failure | Mechanical or electrical breakdown, exceeding operational limits, or manufacturing defects. | Visually inspect equipment for signs of damage, review test data, and consult relevant technical documentation. | Implement regular equipment maintenance, use appropriate safety procedures, and verify equipment specifications. |

Case Studies and Examples

Real-world applications of 4-hour load bank tests demonstrate their crucial role in evaluating power system performance and equipment reliability. These tests, meticulously designed and executed, provide valuable insights into the operational limits and stress tolerance of various components within the electrical infrastructure. Analyzing the results of such tests allows for informed decisions regarding maintenance schedules, system upgrades, and overall operational efficiency.

Power Plant Generator Testing

Thorough testing of power plant generators under simulated load conditions is essential for ensuring reliable operation. A typical 4-hour load bank test involves progressively increasing the load on the generator until it reaches its rated capacity. This procedure allows engineers to assess the generator’s ability to maintain its voltage and frequency output under demanding operational conditions. The results are then compared to the generator’s specifications to identify any deviations or potential maintenance requirements.

- Equipment Used: Load bank with variable output, high-precision voltage and frequency meters, data acquisition system, and monitoring software.

- Procedure Followed: The load bank is progressively loaded to achieve 100% rated capacity of the generator. Data on voltage, frequency, and generator temperature are collected and recorded at regular intervals throughout the test duration.

- Results Obtained: The results indicate the generator’s stable performance at full load, and the ability to maintain voltage and frequency within acceptable tolerances. Deviations from the expected performance parameters highlight potential issues like winding resistance or cooling system efficiency.

Transmission Line Capacity Assessment

Load bank testing can also be employed to assess the capacity and stability of transmission lines. By simulating a high-current load on a specific section of the transmission line, engineers can identify potential voltage drops or thermal stress points. This testing is critical in maintaining the integrity of the transmission infrastructure, especially during peak demand periods.

4-hour load bank tests are crucial for assessing the resilience of electrical systems, particularly under sustained high-demand conditions. For instance, the rigorous testing procedures employed at establishments like golden paramount seafood restaurant richmond , a prime example of a commercial kitchen, highlight the importance of these tests in guaranteeing reliable power supply during peak operating hours. These tests are essential to ensure the electrical infrastructure can handle the anticipated load, preventing potential outages and ensuring consistent operation.

- Equipment Used: Load bank specifically designed for high-current applications, voltage and current sensors, and advanced monitoring systems.

- Procedure Followed: A controlled load is applied to the transmission line section, and the voltage drop, current flow, and temperature of the line components are monitored continuously.

- Results Obtained: The results allow for accurate determination of the line’s capacity under various load conditions. Elevated temperature readings or significant voltage drops may signal potential overloading issues, requiring corrective measures like upgrades or operational adjustments.

Comparison of Load Bank Test Results

| Test Type | Environment | Load Level (kW) | Voltage Deviation (%) | Frequency Deviation (Hz) | Temperature Increase (°C) |

|---|---|---|---|---|---|

| Power Plant Generator | Indoor, Controlled | 1000 | ±0.5 | ±0.02 | 20 |

| Transmission Line | Outdoor, Variable Weather | 500 | ±1.0 | ±0.03 | 35 |

| Distribution System Feeder | Indoor, Controlled | 250 | ±0.8 | ±0.01 | 15 |

The table illustrates a simplified comparison of load bank test results. Actual values may vary based on the specific equipment and test conditions. Factors such as ambient temperature, humidity, and line length significantly influence the results.

Concluding Remarks: 4-hour Load Bank Test Requirements

In conclusion, conducting a successful 4-hour load bank test requires meticulous planning, adherence to safety protocols, and a deep understanding of the test parameters. This guide has equipped you with the knowledge and tools to navigate the complexities of the process, ensuring reliable data and a smooth execution. Remember, proper documentation and analysis are vital to understanding the results and potential areas for improvement.

FAQ Insights

What are the typical voltage ranges for a 4-hour load bank test?

Voltage ranges will depend on the specific equipment being tested, but typically fall within the industry standard parameters.

What safety measures should be taken during a load bank test?

Thorough safety protocols are crucial, including proper grounding, isolation, and monitoring equipment operation.

How can I interpret the data collected during a 4-hour load bank test?

Data analysis involves scrutinizing collected readings, identifying anomalies, and using industry standards for comparison. Graphs and charts help visualise the data.

What are some common issues that arise during a 4-hour load bank test?

Common issues include equipment malfunction, incorrect load application, and insufficient monitoring. This guide provides potential solutions.